Today we’d like to introduce you to Carol Huls

Hi Carol, we’re thrilled to have a chance to learn your story today. So, before we get into specifics, maybe you can briefly walk us through how you got to where you are today?

DittoForm was started by two entrepreneurs in Washington DC in 2014. Allison Lince-Bentley is a sewing instructor who at that time had a sewing studio in Adams Morgan where she taught classes and private lessons. She used dress forms in her teaching to help her students visualize what a pattern would look like when put together. Like all instructors, Allison recognized that most of her students do Not have the size and proportions of a standard dress form. Being a creative person who was interested in technology, she began to ponder ways that 3d imaging might help in the development of a dress form that might more accurately reflect a real human. She and a colleague, Mary Flynn, got together to work out the details: what imaging equipment to use, how to translate it back to a physical model, what materials to use, etc. They launched DittoForm in December 2014.

Word spread quickly through word of mouth and social media. People came to DC to be 3d scanned and purchase a DittoForm. Allison hired me in July 2015 to help a few hours a week with her sewing studio to allow her time to interact with the new clients. Within a few months, the volume of DittoForm clients was so much that Allison and Mary hired Sarah Hull (similar name, but different!) and me to assist with scanning and production. In July 2016, Threads Magazine posted an article about DittoForm and business increased exponentially. In a short amount of time I was working directly with clients in all areas of the business – except the accounting parts.

By December 2017, Allison and Mary were ready to move on to other things. I wanted to join in as a partner – hoping they would stay in the mix for the accounting side and to continue as Founding Creators. Instead they offered to sell me the company. I took a leap and accepted – knowing that I had No Real Idea how to run a company.

Part of my motivation was that I wanted to move back to Michigan. In November 2017 I was diagnosed and treated for DCIS – early breast cancer. Going through treatment in early 2018, I knew it was important for me to be closer to family. In purchasing the company and setting up in Detroit – I would be near family AND in a business environment that would be helpful to a woman-owned small manufacturing business.

I moved to Michigan in May 2018. By 2019 I has gathered a network of support – women business owners, small businesses, consultants, a lawyer, a bookkeeper, etc. I had stars in my eyes – and was still also a deer in the headlights…. I went to Lugano to a 3d body scan conference and stopped in London to talk to makers about the possibility of manufacturing there. The Great Pause (aka Pandemic) in 2020 allowed me time to figure out what I was doing business-wise, take online courses, interact with more business owners (via Zoom) and understand where growth was needed – and where I wasn’t yet ready.…

I have been fortunate that Sarah Hull continues on as a technical contractor working on the images. I found Brian DuBois, a contractor with a skill-set and machinery to do the 3d carving that is a key component of the process.

As we go into 2025 it is incredible to see how DittoForm has evolved and become an even better product. My current team has made over 600 DittoForms together. While no one is standard and every person is unique, some of our clients have significantly asymmetrical shapes due to an illness or accident. Their DittoForm allows them to make clothing for themselves that is comfortable and fits well. It is those cases that really are rewarding and keep me tied to this business.

Alright, so let’s dig a little deeper into the story – has it been an easy path overall and if not, what were the challenges you’ve had to overcome?

If you had told me 20 years ago that I would own and operate a manufacturing business, travelling all over the US to meet customers, I would not have believed you. I did not feel I had the skill sets required to own and operate a company.

But I knew more than I thought and for the things I did not, I learned – everything. From basic accounting to required business filing. Sourcing and production timing. Marketing and advertising: the concept of an ideal customer. Social Media. Right when I was getting the hang of things, the world was shut down due to the Pandemic of 2020-2021. The closures gave me time to take classes, participate in webinars and meet other business owners via Zoom meet-ups hosted by the Small Business Association of Michigan.

After the inital manufacturing delays were over, I needed to find a new way to meet with clients. The Conventions where I had held scanning events were not happening and people were understandably cautious. So instead of people coming to me – I went to clients. I travelled the country solo, with food in my car, stopping only for gas, checking into hotels online (thank you Hilton!). It worked out great for customers. They had the intimate experience of the 3d scan in their own home.

Long term, however, this type of travel is not sustainable without a Lot of Customers. So I’m shifting back to set locations – with goals to still travel to reach most of the country.

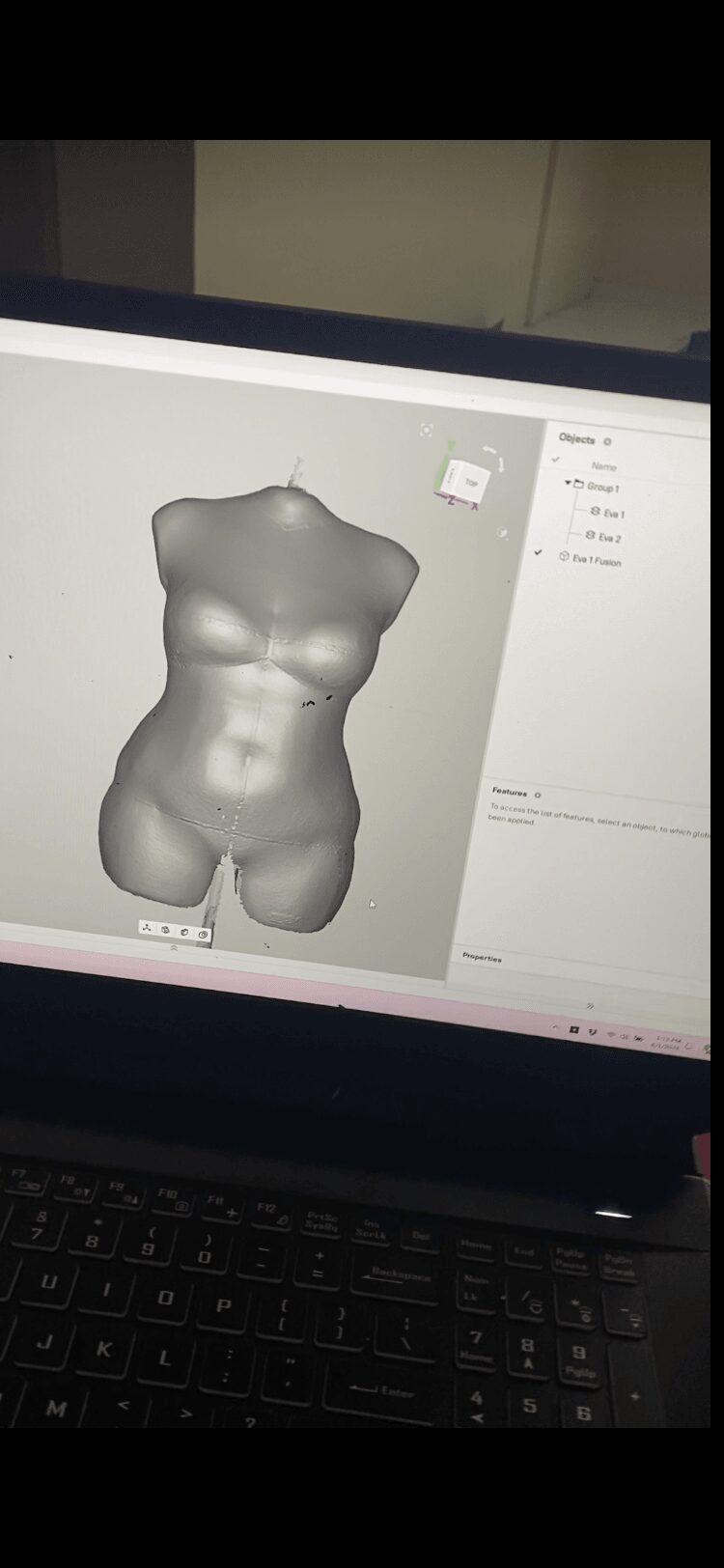

A DittoForm is a product that is Super Cool and Really Helpful to the people that need it, however, it has limitations when it comes to scalability and growth. As a one-to-one custom product, it cannot be mass-produced. As 3d scanning equipment (including phone apps) become more common, it might be possible to make DittoForms from scanned images taken by someone else. At this time, I still strongly prefer to take the images myself. I have the experience of over 600 scans and I know what it is needed for the DittoForm to be made at the high quality that my customers expect. The resolution of the scanner we use (Artec Eva) is very high and captures details and features the phone apps are currently unable to do.

In addition, a DittoForm is a high-end product that is meant for a person who regularly sews their own clothes (or has their own clothes made for them). Our biggest challenge remains reaching people who spend time and money on tools for that purpose. Most of our clients find us through a personal recommendation. Others find us through Threads Magazine – saying they “just found us.” (We have been advertising in that magazine for 8 years). Others through online sewing instructors and cosplayers that feature a DittoForm in their videos. A few are paid partnerships. Others are generous feature spots by fellow business owners that empathize with the struggles of reaching niche markets.

DittoForm’s goals for 2025 include identifying new and innovative ways to find our ideal clients.

Great, so let’s talk business. Can you tell our readers more about what you do and what you think sets you apart from others?

A DittoForm is a life-size model, a custom dress form, created from an image of a specific person. The image is captured using high-resolution 3d scanning technology. Using computer-operated machinery, the image is used to 3d carve a model in a durable, pinable foam. The result is a copy, a ditto, of a real person.

You might be wondering “who would want such a thing?!” People who make their own clothes can save time and money by using their DittoForm as a body double during their design process. They do not have to stop their sewing, change into the partially-done/often still-pinned garment, check the fit, pin or mark the garment on themselves, take it off without hurting themselves, sew a bit and then repeat the process. They can try something on their DittoForm and see how it would fit – on their own body. The cost savings is comes from getting it right the first time and in not making a garment that they will never wear because it does not fit or look right. A DittoForm can be a solution for people who make their own costumes for cosplay, historical reenactments, and specialized festivals. In addition, people who have custom clothes or costumes made for them can send their DittoForm to a tailor or seamstress. Time and money are saved by reducing the number of in-person fittings.

Commercially available dress forms are made in standard sizes based on idealistic measurements – many based on an outdated unscientific study of an “average” American. Most people do not match these standard sizes. In fact, every person is different. Some family members may be similar – but even then, there is always Something about their body that is unique.

Because a DittoForm is created from an image taken directly from a specific person the result is a copy, a ditto, of that real person.

There are a few other companies on the market that make similar products from slightly different methods of capturing the image and/or creating a custom dress form.

DittoForm stands apart as one that hosts travel scan sites, allowing for customers to have easier access to professional scans closer to their home. Most noteworthy is our scanning process: by meeting with me, or one of my personally trained scan technicians, DittoForm clients receive a level of communication and interaction designed to be sure each person is really comfortable with their purchase. The resolution of our scanning equipment was designed for precision engineering – not humans specifically – so the software captures what it sees without making any assumptions or aggregations. DittoForm staff also works hard to be affirming about every person’s body and their choices. This commitment to being non-judgemental and caring is the key component to DittoForm’s brand.

Are there any important lessons you’ve learned that you can share with us?

A key component to a business owner’s success is having connections to other business owners. It is really important to have a community to share ideas, concerns, complaints, joys and generally be a sounding board, especially for sole entreneurs. Once can often feel quite alone in making decisions. When you get a bad review or negativity from one source, you might feel like your whole business is a mistake. Other business owners can provide perspective and remind you of your successes and the positive reviews you have received. Even owners of businesses that are completely different from yours will share stories that will resonate with something you are going through. My best advise to any entrepreneur is to take the time to join associations and attend group meetings to access a kind of support that the best-meaning friends and family simply cannot provide.

*I’ve included a group photo of my Millionare Sewing $quad:

Tricia Camacho, Creative Costume Academy

Katrica Walker, SewKatrina

Jennifer Stern-Hasemann, J Stern Designs

(me!) Carol Huls, DittoForm Michigan LLC

Contact Info:

- Website: https://www.dittoform.com/

- Instagram: https://www.instagram.com/dittoform/

- Facebook: https://www.facebook.com/dittoforms/

- LinkedIn: https://linkedin.com/company/dittoform

- Youtube: https://www.youtube.com/@dittoform

- Other: https://linktr.ee/dittoform

Image Credits

Group photo/my business owner squad (L to R):

Tricia Camacho, Creative Costume Academy

Katrica Walker, SewKatrina

Jennifer Stern-Hasemann, J Stern Designs

Carol Huls, DittoForm Michigan LLC