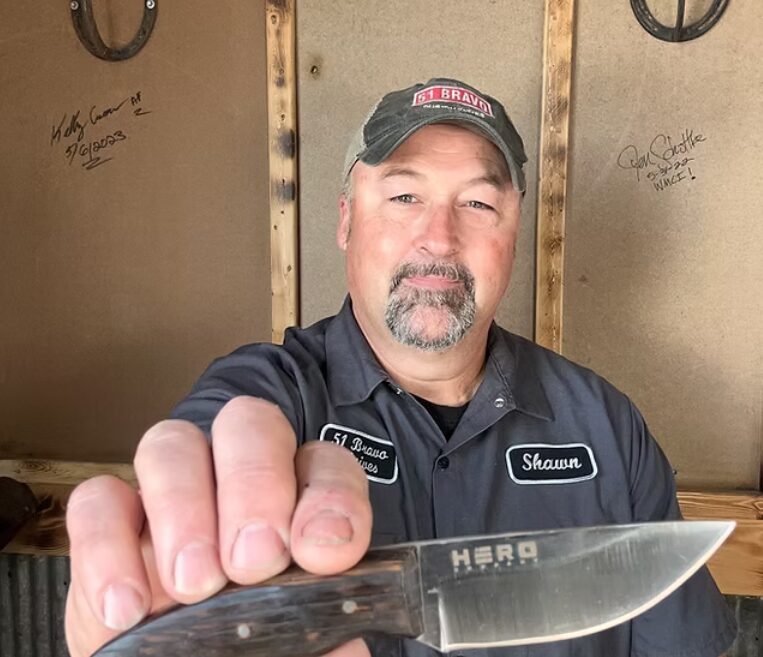

Today we’d like to introduce you to Shawn Moulenbelt.

Hi Shawn, thanks for joining us today. We’d love for you to start by introducing yourself.

I have always been interested in construction and making things. So much so that when I joined the Army out of high school, I chose to train as a 51 Bravo: Carpenter and Mason. I was also a residential builder in the civilian sector for years. About 10 years ago my younger brother Jason started learning to make knives. He kept telling me I should try it, but I was apprehensive because although I knew a lot about wood and other residential construction materials, I knew virtually nothing about working with steel. Eventually I made my first knife from an old file and it wasn’t terrible. Seeing areas to improve on it, I made another one, then another, etc. Fast forward 10 years and I’m still doing that: doing my best work at that time, finding areas to improve and trying to implement those improvements in the next one.

Can you talk to us a bit about the challenges and lessons you’ve learned along the way. Looking back would you say it’s been easy or smooth in retrospect?

For the first 4-5 years knife making was a side hobby with home remodeling being my main form of income. Then came 2020. When everything shut down I was unable to do my job in person, so I began to focus more on my knife making. It actually turned out that sales during the pandemic weren’t too bad. Everyone was cooped up at home making unemployment money and shopping online. So I was able still bring in some income, although for the first 3 years of full time knife making, my wife brought in the bigger income and benefits. I don’t think we would have made it thru those years without her income. Now however, I’m able to hold my own. I don’t make a killing, but I work from home, make my own schedule and make enough to keep the business going.

Thanks – so what else should our readers know about your work and what you’re currently focused on?

One of the things that keeps my interest in knife making is the diversity. There are so many different styles of knives, blade steels and handle materials. Not to mention, swords, daggers, tools, axes, hatchets etc. One day I’m working on a sword, the next on a skinning knife. It doesn’t get boring that’s for sure. For me, knives are heirloom items. Something that gets passed down from one generation to the next. So its important to make a quality blade that incorporates something specific to its owner. Not just simply having their name engraved on it (although that’s nice) but maybe use a piece of antler from a deer they’ve harvested, or use handle materials with their favorite colors. My latest idea of customization has been what I call the “One More Collection”. If a relative has passed on and was cremated, I have taken a small amount of their ashes and incorporated them into the resin of the handle material. This way the customer truly has a physical part of their loved one with them in that knife. If you used to go hunting with grandpa, you can take a knife like this with you and have “One More Hunt” with him. If you loved cooking with your grandmother, you can have a kitchen knife made like this and prepare “One More Meal” with her, etc. I also teach forging classes, many of them are father and son, some are grandpa, father and daughter etc. So I guess that all boils down to tradition, heritage and family. My mission statement is: 51 Bravo exists to create heirloom quality knives worthy of being passed down for generations to come.

Can you talk to us about how you think about risk?

I think just being self employed is a risk. To not have a steady paycheck coming in as long as you show up is risky. Especially with a family: I am married with 3 girls so no income can quickly cause a domino effect. However I still wish I would have taken the risk earlier in life. I worked for other companies until I was 40, always taking the “safe path”. I always thought if a person owns their own business they must know what they’re doing right? Turns out that’s not always the case. I’ve worked for multiple bosses that inherited the business from their parents who really didn’t know how to run a business or manage people.

When people ask me what one piece of advice I would give, I reply with “Start now. Don’t wait too long like I did” I’m not saying quit your current job today, but I am saying start taking daily steps toward doing your own thing. Then when the time is right, take the leap. You can always get another job for someone else if it doesn’t work out. If you’re talented and willing to put in the time, it will work out. Its a risk, but make it a calculated risk and hopefully the rewards will outweigh them.

Pricing:

- Standard hi carbon knives: $175

- Standard Stainless knives: $200

- Forging classes: $150 pp

- Custom jobs: priced upon request

Contact Info:

- Website: https://www.51bravo.com

- Instagram: @51bravo

- Facebook: https://facebook.com/51bravo

- Youtube: @51bravoknives71